Buy your favorite team’s customized 6 DOF Industrial Robotic Arm Control Card with STM32F407 SCARA Stacker Delta Serial Port wifi Android App Machine Vision from the official shop. Shop for your favorite team or player and customize your own product today. You’ll receive the 6 DOF Industrial Robotic Arm Control Card with STM32F407 SCARA Stacker Delta Serial Port wifi Android App Machine Vision in a matter of days, less than most retailers!

DOF Industrial Robotic Arm Control Card with STM32F407 SCARA Stacker Delta Serial Port wifi Android App Machine Vision

6-axis robotic arm control card industrial grade SCARA stacker delta serial port wifi Android App machine vision

Shipping list: 6-axis control card x1, data cable x1

Control card main control chip: STM32F407

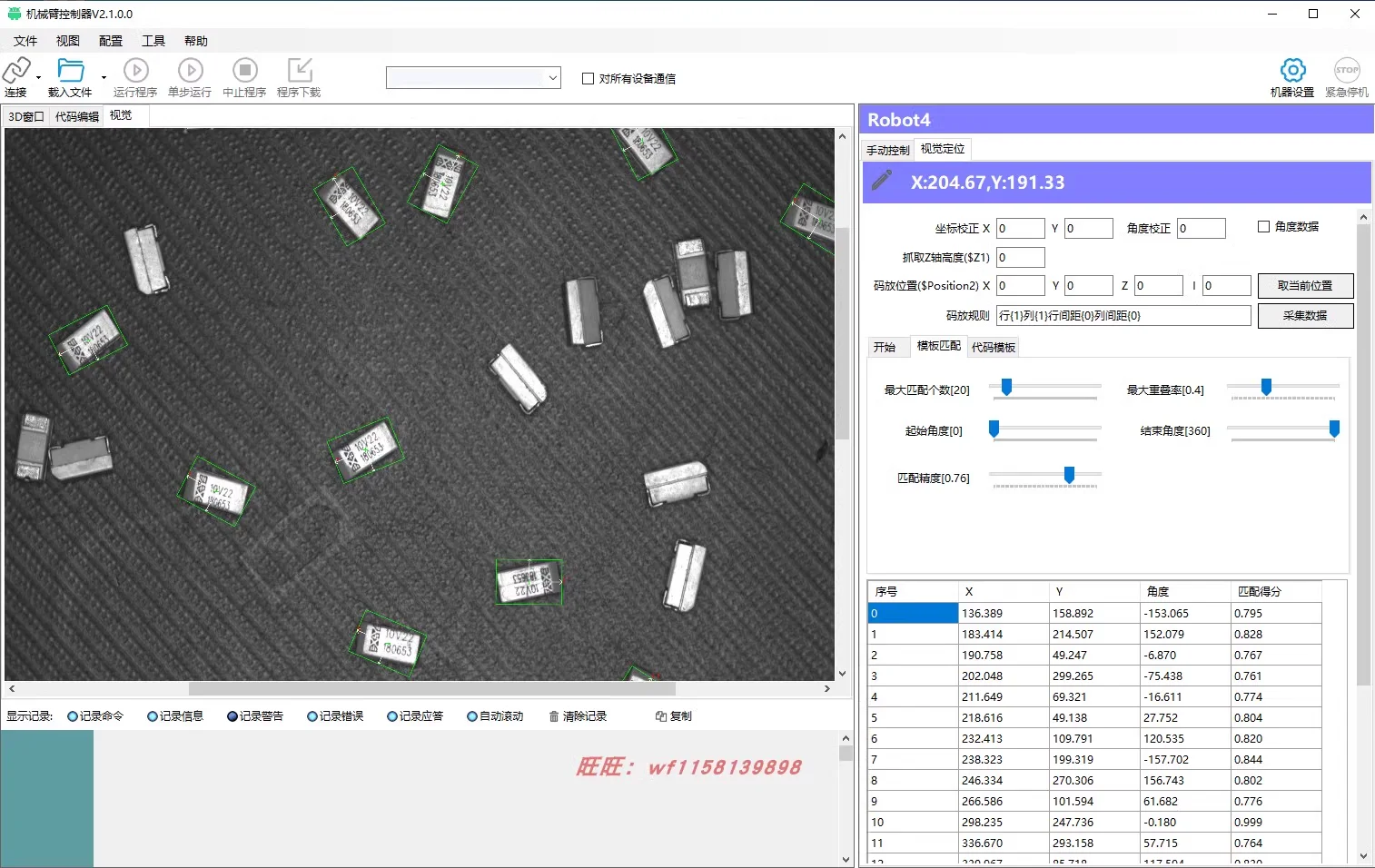

Please note that using visual functions requires a built-in camera (USB interface industrial camera, no distortion lens). The computer system requires Windows 10, Windows 11, and 64 bit systems, otherwise visual functions cannot be used.

Use video tutorial (copy link to browser for viewing)

https://www.bilibili.com/video/BV1RA411n7zK

https://www.bilibili.com/video/BV1si4y1M7jq

Android app teaches programming simple welding trajectories

https://www.bilibili.com/video/BV1si4y1M7jq

Usage of Arc Interpolation Instruction

https://www.bilibili.com/video/BV1p34y1R7Nx?spm_id_from=333.999.0.0

Visual positioning test video

https://www.bilibili.com/video/BV18Y4y1877z?share_source=copy_web

Function Description

1、 Support high-speed optocoupler isolation for controlling 6-way stepper motors or servo motors (5V control signal) pulse signals, and support control of various 3-6 axis conventional robotic arms.

2、 The onboard miniUSB, RS232, and TTL serial ports allow for free selection of communication interfaces, WiFi wireless communication (requiring a WiFi module), and offer Windows and Android apps (compatible with HarmonyOS systems).

3、 9 IO signal outputs (including 5 relay outputs and 4 optocoupler isolated 5V outputs).

4、 6 origin signal inputs, 5 custom program trigger inputs, 1 return to origin signal, 1 cancel pause signal input, all isolated and anti-interference (NPN type, normally open, input voltage 5-24V can be selected).

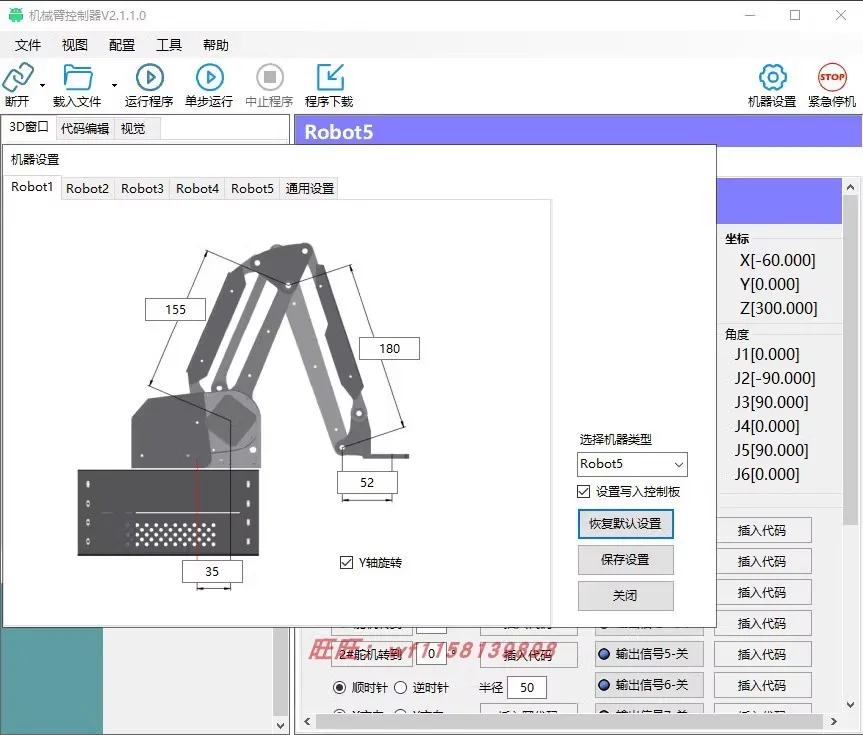

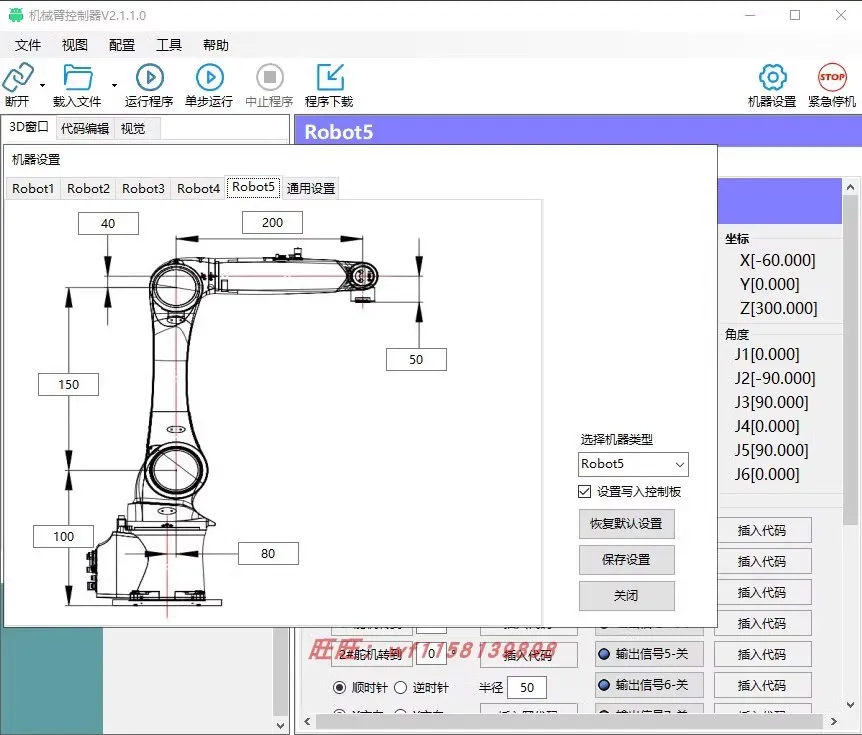

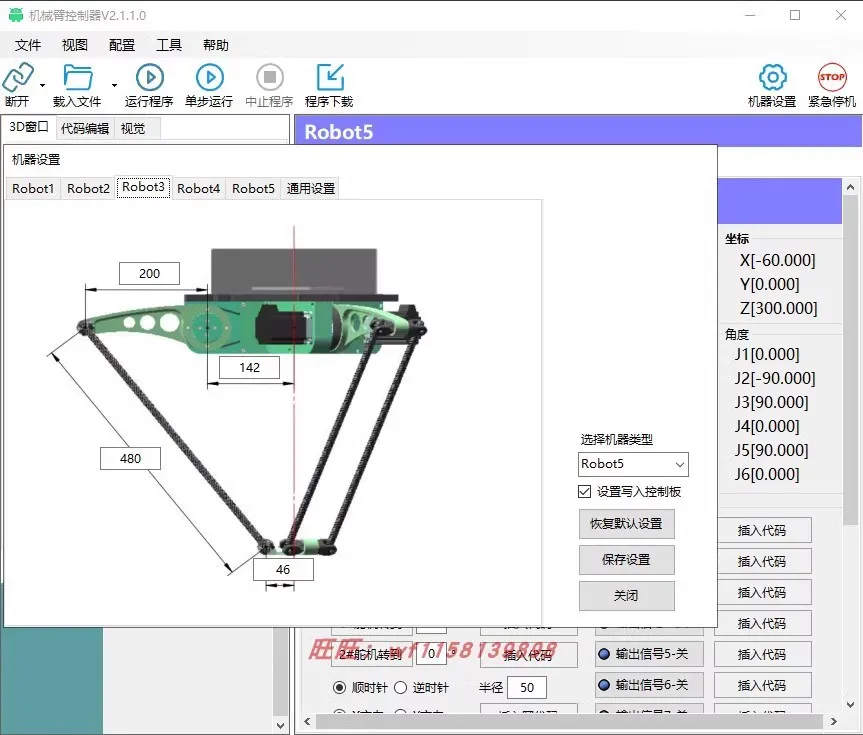

5、 Supports various types of robotic arm structures (stacker crane, SCARA, Delta, standard six axis robotic arm), supports linear arc interpolation, is simple and easy to use, does not require any professional knowledge, and is easy to get started with.

6、 By inserting G code for positional programming, it supports delay and pause (signal triggered end pause), and external signal triggered program operation.

7、 Open communication protocol, which can receive coordinate data sent by other device serial ports and run directly, without the need for users to consider machine kinematic algorithms.

Android APP programming interface

Supports multiple types of machine structures: